Features

- Slow speed operation requires less maintenance, produces more mcfd per horsepower.

- Valve design lets machine run efficiently at lower temperatures.

- Lubricating system features advanced design oil pump and heavy duty oil filter for improved life and reliability.

- Fully counterweighted ductile iron crankshaft is precision ground.

- Crankshaft connecting rods are rifle drilled to assure positive pressure lubrication to all critical wear areas.

- Heavy duty disc type valves with Swedish steel discs, cast iron bumpers and seats for long life.

- Rebuildable high strength aluminum alloy connecting rods equipped with replaceable automotive type inserts.

- Piston pin needle bearings for strength and long life.

- Crankshaft ends are supported by large Timken tapered roller main bearings to withstand radial and thrust loads.

- Large fan-type pulley for smooth running and efficient heat dissipation.

- Circular finned inter-cooler further increases heat dissipation for higher efficiency and longer life.

Single Stage Compression

| MODEL | MAX MCFD | MAX DISCHARGE PSI |

|---|---|---|

| GCP-240-50 QRNG | 237 | 100 |

| GCP-270-50 QRNG | 397 | 100 |

| GCP-4125-50 QRNG | 793 | 100 |

Two Stage Compression

| MODEL | MAX MCFD | MAX DISCHARGE PSI |

|---|---|---|

| GCP-325-30 QRNG | 87 | 400 |

| GCP-340-30 QRNG | 138 | 400 |

| GCP-350-30 QRNG | 167 | 400 |

| GCP-370-30 QRNG | 199 | 400 |

| GCP-5120-15 QRNG | 260 | 400 |

Boss Screw R-Flo Compressor

The Low-Cost, Low-Maintenance Answer to Tough Gas Applications

RO-Flo Compressors Cut Your Operation Costs and Maintain Constant Efficiency

RO-Flo sliding vane, positive-displacement type compressors feature a solid, one-piece rotor eccentrically mounted inside a water- jacketed cylinder. Gas is compressed by being trapped between vanes, which form compartments that become smaller as the gas moves closer to the discharge port. As the volume in these compartments is reduced the pressure is comparably increased until it is equal to the pressure in the discharge port area. Vanes are kept in contact with the cylinder as they wear by centrifugal force, and move in and out of the rotor slots during each revolution. This results in constant efficiency.

Dependable and Cost Effective Ro-Flo Rotary compressors offer:

- Smooth, continuous flow: no reciprocating motion or pulsation. Foundation requirements are minimal

- Ease of maintenance: normal maintenance can be done in field. Blades, seals and gaskets can be inspected and replaced without removing compressor from the system.

- Available in low and high pressure configurations

- Pressures to 175 psig and flows to 6200 acfm (8900 Mscfd) with a +- 5% guarantee on performance.

- Constant efficiency; centrifugal force keeps blades in contact with cylinder as they wear.

Applications

- We have a proven record of performance in applications as tough as:

- Hydrocarbon vapors

- Natural gas/fuel gas

- Coal bed methane

- Landfill gas

- Digester gas

- Acid gas

- Sour gas

- Refrigeration

- Condenser vacuum

- Wellhead pressure reduction

- Process vacuum

- Polymerizing gas Rotary Screw Natural Gas Engine and Rotatory Screw Advantages:

- Rotary Screw compressor is very cost effective for handling high volumes of Gas in Field Gathering

- Low maintenance and High Reliability

- Smooth, Quiet Operation

- Compressor is direct coupled to natural gas engine

General

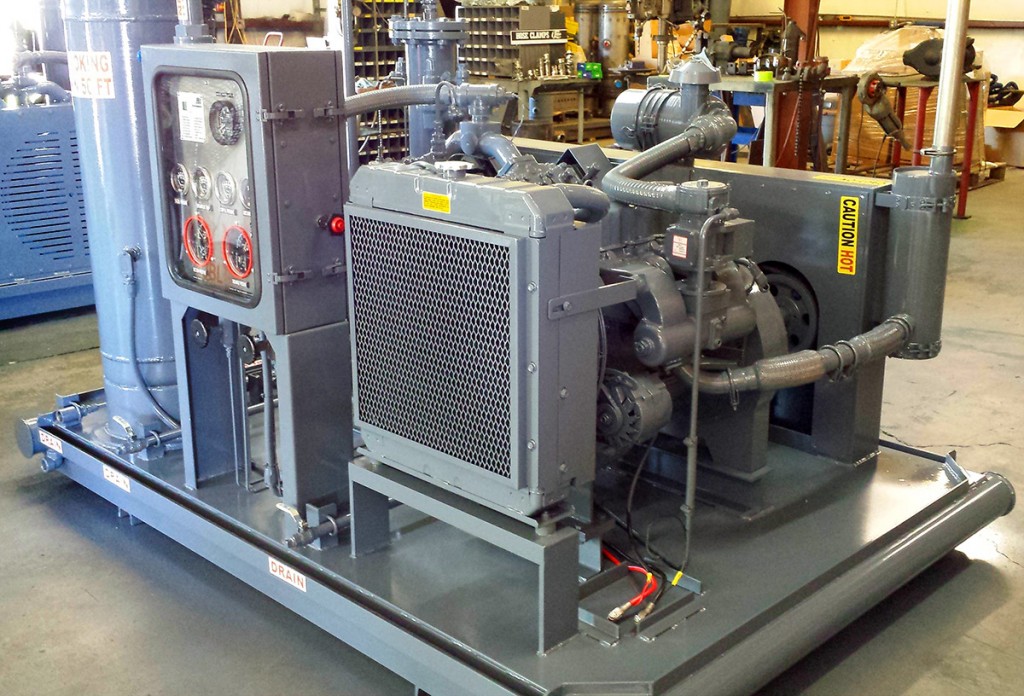

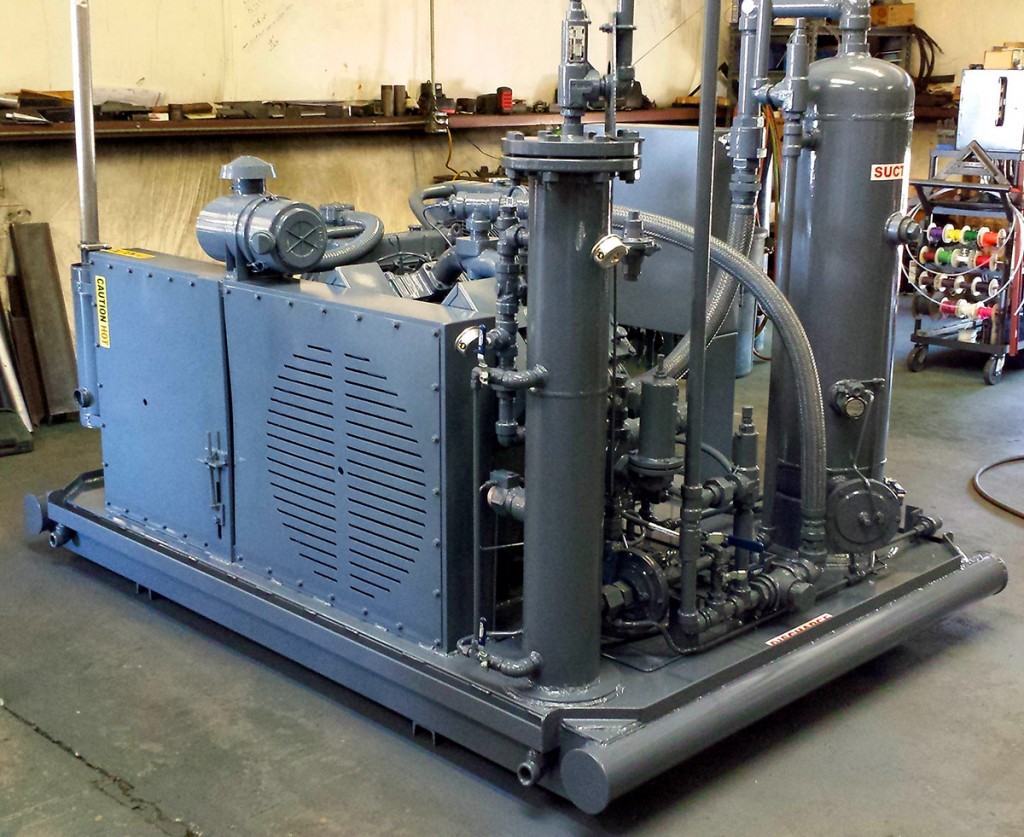

- The Boss Screw comes in either a skid mount or a portable mount on a trailer.

- The Boss Screw comes in two sizes:

GM Vortec 3.0L (4 cylinder) Natural Gas (32HP @ 1800 RPM)

or

GM Vortec 4.3L (6 cylinder) Natural Gas (48HP @ 1800 RPM) - Single stage Rotary Screw Gas Compressor

- Direct Drive Coupled - Gear Driven

- Blower Fan for Cool enclosure and Warm Inlet Scrubber

- Remote Full Flow Engine and Compressor Oil Filers

- Two Stage Engine Air Filter

- Compressor Thermal By Pass Valve

- Gas Differential Pressure Valve for Compressor Oil Circulation

- Automatic compressor blow down value

- ASME Compressor separation Receiver Tank

- ASME Blow Case Inlet Scrubber with Auto Dump and 1- micron filter and Mist Eliminator

- ASME Engine fuel scrubber

- All Vessels protected by Pressure Relief valves

- Engine Radiator

- Compressor Oil Cooler

- gas after cooler (10 degrees F approach) with By Pass

- 12 VDC Heavy duty Maintenance Free Battery with Remote battery jumper posts

- 5 Gallon Automatic Engine Oil Make up System

- Heavy Duty Oil Field Skid Frame

- Acoustical All steel Enclosure with Environment Drip Pan

- Rust Resistant Electrostatic powder Paint